OSIRIS High temperature Test Plant / Hochtemperaturtesteinrichtung OSIRIS HTM Reetz GmbH/ Ilmenauer Glasmaschinenbau GmbH OSIRIS

Basic Information

| Name: | OSIRIS High temperature Test Plant / Hochtemperaturtesteinrichtung OSIRIS | |

| Manufacturer: | HTM Reetz GmbH/ Ilmenauer Glasmaschinenbau GmbH | |

| Model: | OSIRIS | |

| Facility: | Chair of Hydrogen and Nuclear Engergy (WKET) | |

| Partner: | Technische Universität Dresden (TUD) | |

Description

OSIRIS ist ein gasbeheizter Kammerofen im Labormaßstab für Materialuntersuchungen in oxidierender Wasserdampfatmosphäre im Temperaturbereich bis ca. 2100 ºC.

| Regel- und Meßtechnik | Parameter |

|

|

***********English***********

OSIRIS is a gas heated batch furnace in a laboratory scale to conduct research of materials in oxidizing steam atmosphere on a temperature range of approx. 2100°C.

The research of materials in an oxidising steam atmosphere in a temperature range of 2000 °C conducted within the framework of nuclear security research of the chair of energy technology requires a batch furnace that endures the conditions arising during long term experiments and enables quick transient test procedures..

There are – apart from some ion conducting oxides – no materials resisting this temperature and thus can be used as electric resistance heating. Ion conducting oxides have a strong negative temperature coefficient that impedes the temperature controlling and the power supply. Furthermore, the thermo shock resistance of these oxides is very poor.

Alternative heating methods are:

Arc load, plasma, laser, induction heating or chemical reaction. The creation of an isothermal experiment space with the help of the first three methods is very difficult. The direct induction is bound to a geometrical stable, electrical conductive assay.

A gas heated batch furnace is the most suitable alternative to face the requirements. The combustion of hydrogen and oxygen delivers sufficient energy in order to achieve the required temperature range as well as the necessary reactive furnace chamber atmosphere.

The test plant Osiris was designed in cooperation with HTM Reetz GmbH and Ilmenauer Glasmaschinenbau GmbH. The detailed planning and the execution of construction work were carried out by HTM Reetz GmbH. Ilmenauer Glasmaschinenbau GmbH developed and delivered the burner technology.

The plant was brought on line early in 1999. The plant features a remarkably good temperature controlling. Furthermore, there are no restrictions concerning the operation during start-up procedure and rundown.

Link to Further Details

Options of instrument usage

- This instrument is used within a service or research collaboration.

Points of Contact

Notes

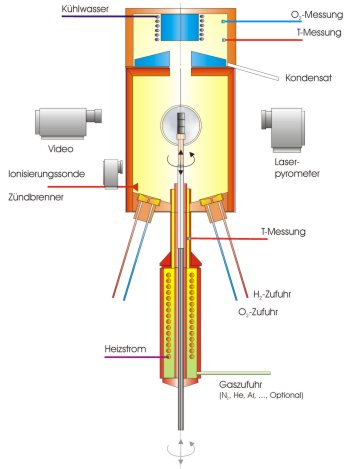

In dem geschlossenen Ofenraum stehen die Werkstoffproben frei oder in einem ZrO2 -Rohr in Schutzgas im Zentrum von vier außenmischenden H2/O2-Brennern. Dem Versuchsraum ist ein Wärmetauscher nachgeschaltet, in dem das Abgas kondensiert. Die zur Regelung notwendige Temperaturmessung erfolgt im unteren Temperaturbereich durch ein frei positionierbares Thermoelement Typ B und im oberen Temperaturbereich pyrometrisch. Zur Anwendung kommt hier ein Laserpyrometer, das zeitgleich mit der Temperatur durch Laserreflexionsmessung den Emmissionsgrad der Meßoberfläche bestimmt und den Temperaturwert entsprechend ermittelt.

Kommt ein zusätzliches Spülgas zur Anwendung, kann dies durch eine elektrische Zusatzheizung bis 1000 °C vorgeheizt werden. Die Werkstoffproben sind durch ein Probenpositionierungssystem im Ofenraum verfahrbar.

***********English***********

Control and Measurement Technique

- Automatic nominal value control

- Computer controlled data collection system

- Laser pyrometer

- O2 Measurement

- Video recording

Parameter

- Top long term operation temperature 2000°C

- Heating rate 1000K/ min

- Cooling rate maximal natural cooling

The samples are either free-standing in the closed burning chamber or in a ZrO2 pipe covered in inert gas in the centre of four external H2O2 burners. Emission precipitates in a downstream heat exchanger. On a lower temperature scale a free positioning thermo element Type B measures the temperature in order to execute the control. On a higher temperature scale the measurement is pyrometric. A laser pyrometer measures synchronically the temperature and the degree of emission of the testing surface via laser beam measurement.

If a flushing gas is required, it can be pre-heated up to 1000°C. With the help of a sample positioning system the samples are manoeuvrable in the furnace chamber.

Associated Services

| Name | Preview | Actions |

|---|---|---|

| Materialuntersuchungen in oxidierender Wasserdampfatmosphäre im Temperaturbereich über 2000 ºC |

Images

Last Update

Last updated at: 13 July 2017 at 11:54:12

View all instruments of this unit

View all instruments of this unit